3D Printing: The Unsung Hero of the Smartphone Thinning Revolution, Xiaomi and Apple Vie for the Lead

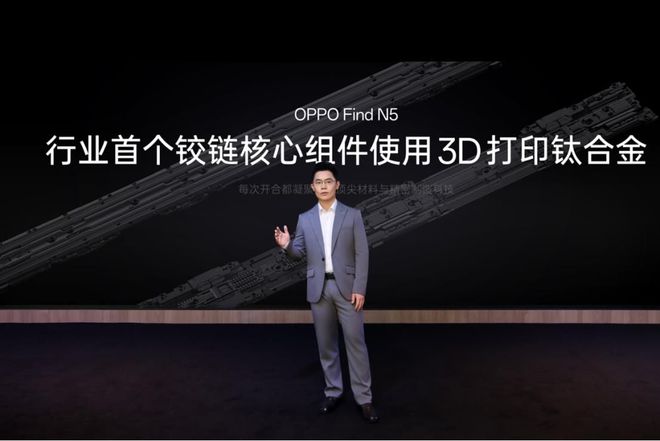

3D Printing: The Unsung Hero of the Smartphone Thinning Revolution, Xiaomi and Apple Vie for the LeadAbout two weeks ago, OPPO launched the Find N5, with its "3D-printed titanium alloy sky-hinge" as the main highlight. However, many overlooked the significance of the "3D printing" technology itself

3D Printing: The Unsung Hero of the Smartphone Thinning Revolution, Xiaomi and Apple Vie for the Lead

About two weeks ago, OPPO launched the Find N5, with its "3D-printed titanium alloy sky-hinge" as the main highlight. However, many overlooked the significance of the "3D printing" technology itself. Renowned analyst Ming-Chi Kuo recently predicted that Xiaomi will adopt 3D-printed metal frames in its Xiaomi 16 Pro, slated for release by the end of 2025 a first in the mobile phone industry. Previously, OPPO Find N5 pioneered the use of 3D printing for its foldable screen hinge, and Honor Magic V2 also utilized it for its hinge cover. Apple, too, has begun using 3D printing for some titanium components in the Apple Watch Series 9.

3D printing technology is gradually transitioning from high-end foldable phones to mainstream flagships. However, Xiaomi's claim to be the first to globally launch a phone with a 3D-printed metal frame remains uncertain, as reports suggest that the iPhone 17 Pro also plans to adopt this technology.

While this technological application might seem like a mere upgrade in manufacturing processes, its impact on consumer experience could be far greater than anticipated. What changes will the 3D-printed metal frame in the Xiaomi 16 Pro or iPhone 17 Pro bring?

Thinner Than Thin: 3D Printing Achieves New Levels of Lightness and Thinness

The hinge system is the core mechanical structure of a foldable phone, directly affecting its reliability and user experience. A thinner, stronger hinge has been the constant pursuit of foldable phone manufacturers. The Honor Magic V2, released in 2023, touted itself as "the world's thinnest foldable phone," with an unfolded thickness of just 4.7mm and a folded thickness of 9.9mm. This was achieved thanks to Honor's collaboration with AAC Technologies, using 3D laser-printed titanium alloy hinge covers for a lighter, thinner, and more robust structure. This marked the first large-scale application of 3D printing technology in the mobile phone industry.

OPPO Find N5 went even further, directly employing 3D laser printing to manufacture its "titanium alloy sky-hinge" (wing plates and outer middle frame), reducing the folded thickness to 8.93mm. OPPO chose titanium alloy for its combination of lightness and strength. Achieving a super-thin thickness of 0.15mm on the wing plates is almost impossible with traditional CNC machining; 3D printing allows for one-time printing with accuracy of 0.02mm, significantly improving structural strength.

The growing preference for 3D printing, especially with titanium alloy materials, is linked to the cost and performance limitations of traditional CNC machining. Traditional CNC machining has low material utilization, high costs, and complex structures resulting in longer processing times and higher scrap rates. Titanium alloy is expensive and tough, making traditional processing even more costly and wasteful, and the realization of complex structures extremely difficult.

3D printing fundamentally resolves this conflict, producing complex components with virtually zero waste, reducing weight, improving heat dissipation, and thus enhancing the overall product experience. Traditional hinge production requires complex forging, cutting, and polishing processes, resulting in low yield rates. 3D printing, through layer-by-layer material accumulation, prints complex structures in one go, achieving near 100% material utilization and significantly improving precision and strength. It can even create hollow structures impossible with traditional methods. The material cost of titanium alloy is not the biggest expense; the truly expensive part is the processing cost. According to industry media reports, the material cost of the Honor Magic V2's titanium alloy hinge cover is approximately RMB 30, but the processing cost is as high as RMB 200-300, making it the most expensive module in the foldable screen structure.

3D Printing: The Deciding Factor in the Smartphone Thinning Revolution?

OPPO and Honor's application of 3D printing technology in high-end foldable phones can be considered a "test run," while Xiaomi and Apple's deployment of this technology in mainstream flagship models demonstrates the industry's deeper acceptance.

If Xiaomi 16 Pro and iPhone 17 Pro successfully integrate 3D printing technology, smartphone manufacturers will further optimize phone weight and feel. Traditional CNC-machined frames, while precise, are wasteful and expensive, hindering the pursuit of ultra-thin designs. 3D printing breaks this bottleneck, improving material utilization and giving phone designers greater creative freedom. The phone frame will no longer be a simple structural component but can evolve into a functional part with complex hollow structures and precise heat dissipation micro-channels.

This new process helps manufacturers overcome the limitations of traditional manufacturing methods, achieving true thinness and structural breakthroughs in smartphones. The emergence of the ultra-thin Samsung Galaxy S25 Edge (5.84mm thickness) signals an upcoming "thinning" wave in the mobile phone industry. Titanium alloy materials and 3D printing processes are crucial in this "weight reduction" endeavor.

The current focus in the smartphone industry has shifted from hardware specifications to the optimization of complex functions. Manufacturers are pursuing on-device AI, large-sensor cameras, and flagship models are incorporating larger camera modules, more powerful chips, and larger batteries, leading to challenges in heat dissipation, structure, and weight. 3D printing offers new solutions to these problems, leveraging the high strength and low weight of titanium alloy, and the ability of 3D printing to create complex hollow structures to address heat dissipation and lightweight issues.

Theoretically, 3D printing technology can be applied to various components of a phone. In the future, smartphone manufacturers may achieve unprecedented heat dissipation optimization designs within the phone frame, or lightweight support structures around larger CMOS camera modules. The transition from CNC machining to 3D printing might be a crucial step in the ongoing AI and camera battle among flagship models. The thinness and strength of a phone directly affect the user's grip, while better heat dissipation determines whether power-hungry features like AI and advanced cameras can fully unleash their potential.

Apple's Entry and the Challenges of 3D Printing Scalability

The large-scale production of 3D-printed core components for smartphones still faces numerous challenges, such as high equipment investment costs, dimensional accuracy consistency issues after scaling up, and production efficiency issues. These are hurdles faced by leading manufacturers like Apple, Xiaomi, OPPO, and Honor.

Kuo has pointed out that although some Apple Watch components are already 3D-printed, production efficiency has improved but still requires CNC post-processing. This may be the reason why Apple has not yet introduced 3D printing technology to the iPhone.

Honor and OPPO's introduction of 3D printing to foldable phones is, on the one hand, due to the more obvious pain points of foldable screens, which 3D printing can significantly improve; on the other hand, the ultra-high-end positioning of foldable phones allows them to withstand higher costs. Simply put, the return on investment makes sense, making 3D printing a natural choice.

Whether 3D printing is suitable for mainstream flagship phones and can deliver reasonable returns still needs further confirmation. Any technological leap is arduous, but behind this lies the opportunity for a true breakthrough in the manufacturing of mobile phones and consumer electronics, just as Apple initially introduced CNC machining to the MacBook.

A 3D-printed titanium alloy frame may simply be a process upgrade, but it may hold the next key to the continued evolution of smartphones. Whether Xiaomi or Apple will be the first to complete this revolution is a question worth anticipating.

Tag: the 3D Printing The Unsung Hero of Smartphone Thinning

Disclaimer: The content of this article is sourced from the internet. The copyright of the text, images, and other materials belongs to the original author. The platform reprints the materials for the purpose of conveying more information. The content of the article is for reference and learning only, and should not be used for commercial purposes. If it infringes on your legitimate rights and interests, please contact us promptly and we will handle it as soon as possible! We respect copyright and are committed to protecting it. Thank you for sharing.