The first fully 3D printed flexible OLED display screen is available

Science and Technology Daily, Beijing, January 12 (Reporter Liu Xia) - American researchers pointed out in the latest issue of the journal "Progress in Science" that they have printed the first flexible organic light-emitting diode (OLED) display screen using a customized printer. This display screen is made of 3D printing, without the need for expensive micro processing equipment in the past

Science and Technology Daily, Beijing, January 12 (Reporter Liu Xia) - American researchers pointed out in the latest issue of the journal "Progress in Science" that they have printed the first flexible organic light-emitting diode (OLED) display screen using a customized printer. This display screen is made of 3D printing, without the need for expensive micro processing equipment in the past.

OLED display technology uses organic material layers to convert electricity into light, and has a wide range of applications. It can be used as large devices such as television screens and displays, as well as handheld electronic devices such as smartphones. It is widely popular due to its lightweight, energy-saving, thin and flexible, wide viewing angle, and high contrast.

Michel McCarpin, senior author of the latest research and department of mechanical engineering at the University of Minnesota, said, "OLED displays are typically produced in large, expensive, and ultra clean manufacturing facilities. We want to see if we can compress the process flow and print them using our customized desktop 3D printer ('worth' is similar to a Tesla S-car)

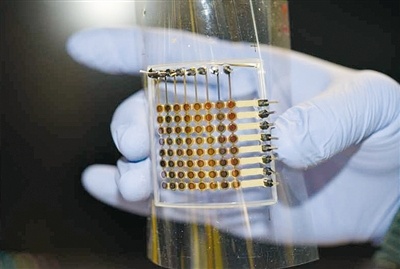

The research team has previously attempted to print OLED displays using 3D printers, but was unable to achieve uniform and consistent light emitting layers. In the latest research, they took a different approach and combined two different printing modes to print six Mechanical floor, and finally printed the first flexible OLED display completely made by 3D printers. Among them, the electrodes, interconnections, insulation, and packaging layers are all obtained through extrusion printing, while the active layer is sprayed and printed using the same 3D printer at room temperature. The prototype of the monitor has a side length of approximately 3.8 centimeters and has 64 pixels, each of which can function normally.

Su Ruitao, the lead author of the latest research and a doctoral graduate of mechanical engineering from the University of Minnesota, said that the new 3D printing display screen is very flexible and can be packaged in other materials, which makes it widely used in many fields. Experiments have shown that the display screen remains stable after 2000 bends, indicating that fully 3D printed OLEDs may be suitable for use in flexible electronic and wearable devices.

The researchers next plan to use 3D printers to print OLED displays with higher resolution and brightness.

Tag: The first fully 3D printed flexible OLED display screen

Disclaimer: The content of this article is sourced from the internet. The copyright of the text, images, and other materials belongs to the original author. The platform reprints the materials for the purpose of conveying more information. The content of the article is for reference and learning only, and should not be used for commercial purposes. If it infringes on your legitimate rights and interests, please contact us promptly and we will handle it as soon as possible! We respect copyright and are committed to protecting it. Thank you for sharing.